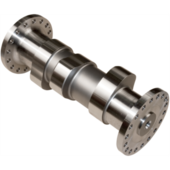

Demanding machining services and assembly

Our extensive machine and support equipment portfolio enables completing in-house all the manufacturing steps even for the most complicated components. We have the highest efficiency in manufacturing components in size range 1–2500 kg.

We have experience in efficient manufacture of both low volume and high mix and high volume and low mix series. As a raw material we typically use high quality forgings, bar materials, and castings.

To provide our customers full traceability, all our components include serial numbers. Excellent quality documentation and statistical performance control in our production assure that we meet all customer requirements.

We have externally audited ISO 9001, ISO 14001 and OHSAS 18001 systems as well as delivery approval for nuclear applications.

Purso-Tools is proud of delivering the most demanding components and assemblies to well known global machine and engine manufacturers. We ensure that our customers can build the highest quality products and brands by using our components.

Our serial numbering system ensures traceability of all documentation (raw material certificates, heat treatment certificates, NDT certificates, measuring documents, etc.) for a minimum of ten years after delivery.